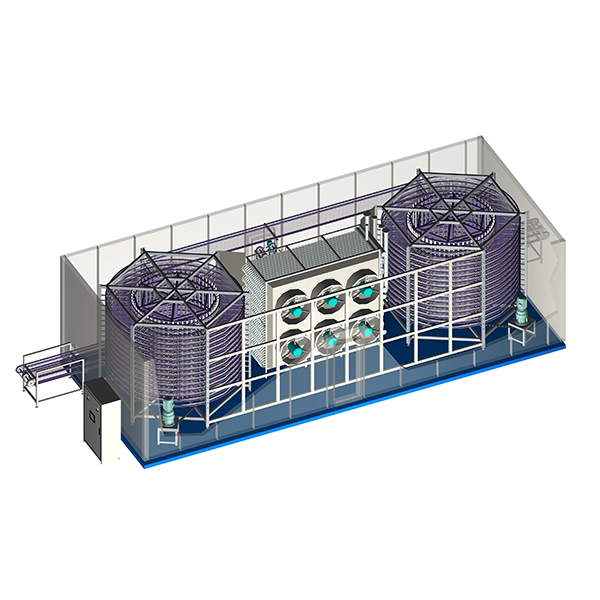

In the food processing and cold chain logistics sectors, quick-freezing technology has always played a key role. Its development has not only been a breakthrough in speed but also a continuous commitment to quality. Early quick-freezing technology primarily relied on tunnel freezing, which relied on long freezing times to cool ingredients. While this met basic preservation requirements, it could easily lead to cell rupture and moisture loss, impacting both taste and nutritional value. As industry demands evolved, spiral quick-freezing equipment emerged. Its three-dimensional layout shortens the freezing path, increasing freezing efficiency by over 30%. Combined with a precise temperature control system, it rapidly reduces the core temperature of ingredients to below -18°C, preserving cellular integrity to the greatest extent possible.